Expertises = fct(métiers)

Matrice de compétences métiers

Carbody

Recherche de concept structurel innovant multi-materiaux

Crash & Biomécanique

Qualification des exigences de confort et de sécurité de marche

Dynamique

Qualification des exigences de confort et de sécurité de marche

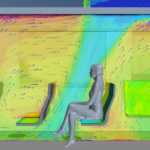

Confort climatique

Optimisation du confort climatique voyageurs

Thermique

Optimisation du refroidissement des équipements (coffres de traction, …)

Aérodynamique

Détermination des efforts aérodynamiques

Acoustique

Évaluation des phénomènes aéro et vibroacoustiques

Chocs & Vibrations

Prédiction de la résistance aux sollicitations vibratoires

Éco-conception

Accompagnement a l’analyse du cycle de vie (ACV)

Matrice de compétences métiers

Primo conception

Recherche de concept structurel innovant

Épreuve & Fatigue

Tenue mécanique aux charges de services et exceptionnelles

Accostage

Performances des sous-ensembles (absorbeurs, barres d’accouplement)

Expertise technique

Audit de défaillances et prolongation de la durée de vie des matériels

Dynamique

Qualification des exigences de sécurité de marche (refoulement, …)

Maintenance 4.0

Monitoring du matériel roulant et définition des profils de vie

Matrice de compétences métiers

Vulnérabilité

Études et qualifications des équipements et systèmes clés (PàC, réservoirs, …)

Protection

Effets du blast sur l’intégrité structurelle & biomécanique

Matériaux

Caractérisation des lois matériaux à hautes vitesses de déformations

Fiabilité

Prédiction de la durée de vie & dimensionnement en fatigue

Acoustique

Évaluation des phénomènes aéro et vibroacoustiques

Architecture

Optimisation du ratio poids / puissance

Thermo-fluidique

Couplage thermo mécanique et refroidissement des équipements clés

Combustion

Qualification des performances de combustion

Data management

Simulation multiphysique (MDO) et plans d’expériences automatisés

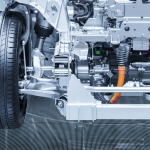

Matrice de compétences métiers

Crash & Certification

Dimensionnement par cosimulation et plan d’expériences automatisé

Vulnérabilité

Étude et intégration des équipements clés (pac, batteries, réservoirs)

Fiabilité

Validation en fatigue du châssis et des équipements embarqués

Dynamique véhicule

Évaluation du comportement châssis (exigences de confort et de sécurité)

Éco-conception

Accompagnement à l’analyse du cycle de vie (ACV)

Thermo-mécanique

Fatigue thermo-mécanique et refroidissement des équipements clés

Maintenance 4.0

Prolongation de la durée de vie des matériels en exploitation

Autonomie

Optimisation de la consommation des équipements embarqués (HVAC, …)

Data management

Optimisation multi-disciplinaires (MDO) et plans d’expériences automatisés

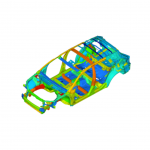

Matrice de compétences métiers

Allègement

Stratégies d’optimisation & lightweight conception

Sécurité passive

Dimensionnement au crash & évaluation des systèmes de retenue

Durabilité

Prédiction de la durée de vie & dimensionnement en fatigue

Dynamique véhicule

Évaluation des performances de sécurité et de confort dynamique

Thermo-fluidique

Validation des exigences de compatibilité thermique des équipements (batteries, …)

Vibroacoustique

Vérification des exigences NVH (Noise, Vibration & Harshness)

Matrice de compétences métiers

Résistance

Étude de scenarii exceptionnels (effondrement, séisme et incendie)

Dispersion AtEx

Dispersion atmosphérique de substances inflammables / explosives

Explosion

Simulation d’explosion et interactions Fluide-Structure

Thermique

Optimisation du refroidissement des équipements

Maintenance 4.0

Surveillance de l’évolution de l’endommagement structurel

Vibrations

Dimensionnement des dispositifs d’amortissement et de filtration

Acoustiques

Étude des perturbations acoustiques (sources solidiennes et aériennes)

Éco-conception

Accompagnement a l’analyse du cycle de vie (ACV)

Supervision

Optimisation du rendement des installations